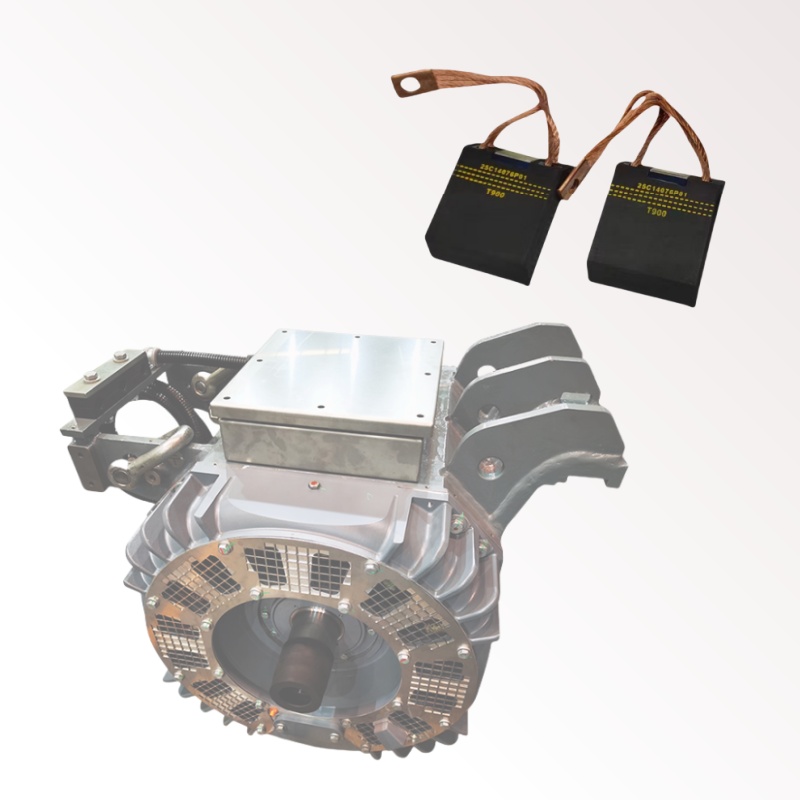

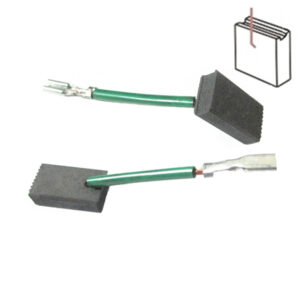

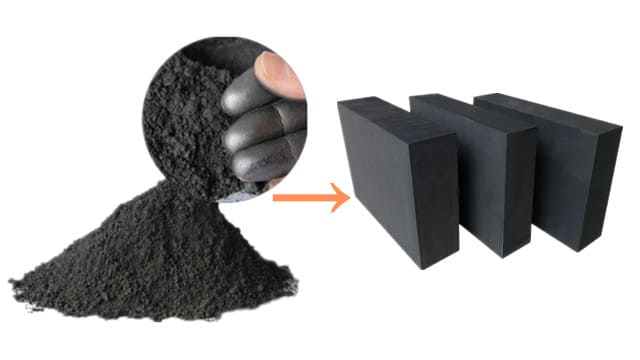

Railway & Mining Carbon Brushes - Engineered for Extreme Duty Cycles

High Quality, High Standards

-

EN 45545-2, MSHA

-

45% Downtime Reduction

-

Custom Designs (e.g., Explosion-Proof)