Precision for Pulp Perfection

Heat-Resistant, Always Reliable

-

Less Downtime

-

High Heat Resist

-

Low-Dust Output

Heat-Resistant, Always Reliable

007Carbon delivers precision-engineered brushes for:

Refiners/Grinders – Abrasion-resistant

Dryers – 150°C+ stable

Winders – Low-spark, high-speed

Wet-Ends – Chemical-proof

Why Choose Us:

✓ Longer lifespan – 30-50% over OEM

✓ Cleaner runs – Low-dust design

✓ Faster swaps – Standardized sizing

Proven in 24/7 global mills – Custom solutions available.

Our main products include … and other products.

They meet the various scenarios used in … and other usage scenarios.

We provide brilliant solutions and add the world called success to your brand.

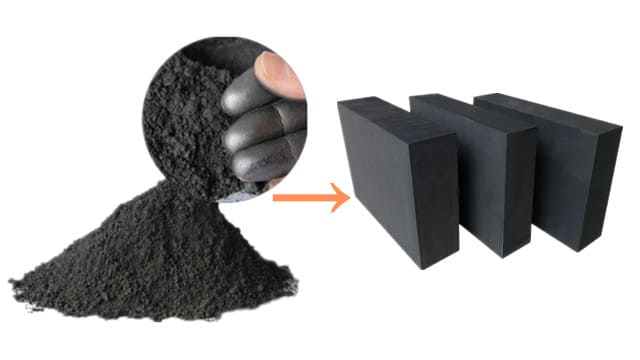

Customize the Pulp and Paper carbon brush material to your equipment, from graphite powder to graphite blocks.

Customize the appearance of your favorite Pulp and Paper carbon brush, such as miter, grain, engraving, printing.

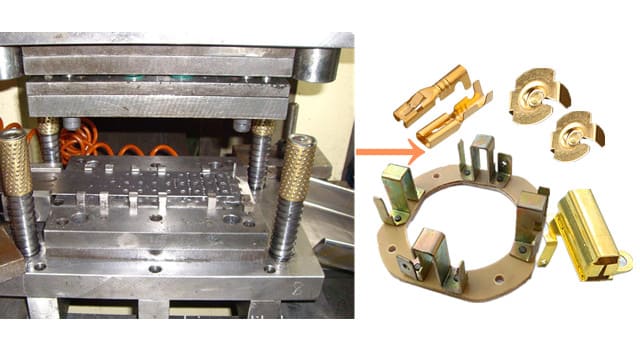

Customize kinds of brush holder mould service, such as joints, brush holder,plastic plate and so on.

Customize all kinds of Pulp and Paper carbon brush spring, mainly pressure spring, torsion spring, vortex spring.

Provide customized Pulp and Paper carbon brush wire service, mainly twisted wire, braided wire and tinned wire.

Provide customized packaging design and humanized service, with cartons, polybag bags, hanging cards and so on.

With our modern equipment and the craftsman spirit of our staff, we offer endless possibilities for carbon brush customization.

We believe quality is always the key to success, which includes a responsible approach to manufacturing, and controlling whole process.

Make Pulp and Paper carbon brush drawings according to your requirements.

Choose the suitable carbon block material that fits your motors.

Cut into small carbon blocks from whole carbon material.

Grind carbon block surface,make it fine and smooth.

Measure carbon body size,tolerance rate is controlled at -0.1mm to 0mm.

Drill a hole into carbon body.

Bury copper wire into hole of brush body.

Fasten terminal by welding or biting cable.

At 007Carbon, We turn complex Into Simple! Follow the following 4 steps to start today.

Tell us as specific as possible of your needs, provide the drawing, reference picture and share your idea.

We will work on the best solution according to your requirements and drawing, the specific quote will be provided within 24 hours.

After approving the quote and solution, we will prepare the prototyping sample for you in 3-5 days. You can confirm this by physical sample or picture & video.

We will start mass production after getting your approval and deposit, It generally will take 15-20 days, and we will handle the shipment.

007carbon covers the full kinds of carbon brush allowing you to get the suitable solutions for your goals.Talk with our custom carbon brush experts and find out how we can help elevate your business.

Withstands 24/7 abrasive pulp processing

Stable in 150°C+ dryer section conditions

Minimizes paper contamination risks

Ensures smooth calendar roll operation

Handles humid, chemical-rich environments

Industry-standard sizing for minimal downtime

Have Any Questions? Find possible answers below or contact our team for any questions.

Yes! Our heavy-duty carbon brushes are engineered for continuous operation in abrasive environments, with reinforced materials that resist wear from wood fibers and chemicals.

Our low-dust formulations and precision-sealed designs minimize particulate release, meeting strict paper quality standards for clean production lines.

Standard orders ship in 10-14 days. We keep common sizes in stock for emergency 72-hour deliveries to minimize production downtime.

We precisely replicate all OEM dimensions and performance characteristics, often improving lifespan by 30-50% through material upgrades.

Our thermal-stable composites maintain optimal conductivity even at 150°C+, preventing premature failure in dryer cans and calenders.

Yes, our polymer-impregnated brushes resist steam, acids, and alkalis common in pulping and bleaching stages.

Our silver-graphite blends and anti-spark geometries cut arcing by 60%, protecting motor windings in high-load grinding applications.

We engineer low-friction brushes with wear indicators for winders operating at 1,500+ meters/minute, ensuring smooth roll changes.

Driven by the flexibility of the material and our exquisite craftsmanship, there is an unlimited possibility of custom Pulp and Paper Carbon Brush at 007Carbon.

Whether you have a drawing, prototype sample, or just a reference picture.

Please pay attention to the email with the suffix “@007carbon.com”.

Your information will be kept strictly confidential.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Allow file type: pdf, jpg, png (less than 20M)