And Why Their Failure Stops Your Laundry

The Silent Power Couriers Inside Your Washer

① The Core Mechanism – Simplifie

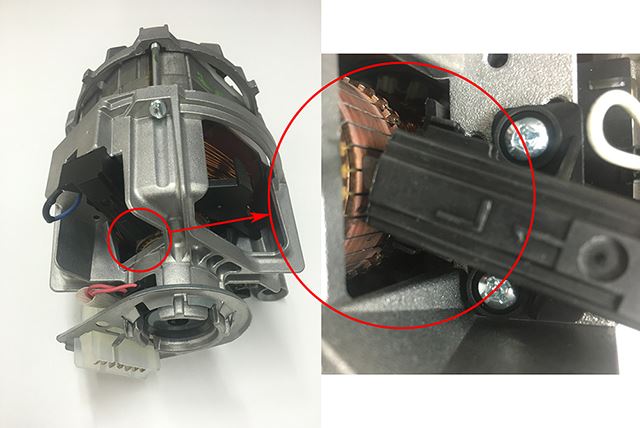

Carbon brushes are the motor’s electricity delivery team. Think of them as two spring-loaded graphite “fingers” (see highlighted image below) that:

- Press against the spinning armature (a copper coil cylinder)

- Transfer electricity from the power source to the armature

- Create electromagnetic force that makes the armature – and ultimately the drum – rotate via the drive belt.

Key Design Insight

Their spring mechanism acts like a persistent handshake, ensuring constant contact even as the armature spins at high speed.

② What Happens When They Wear Out?

The Domino Effect of Worn Brushes

- Stage 1: Graphite erosion from friction reduces brush length → Springs can’t compensate anymore.

- Stage 2: Intermittent sparking occurs → Electricity transfer becomes unstable.

- Stage 3: Complete disconnection → Motor loses power → Drum freezes mid-cycle.

You’ll Know It’s Them If

✅ Machine fills with water but drum doesn’t budge

✅ Wash/spin cycles “run” silently (no motor hum)

✅ Clothes emerge soaking wet despite “completed” cycle

③ Why Carbon Brushes Fail Faster Than Other Parts

(Builds Technical Credibility)

| Factor | Impact on Carbon Brushes | Typical Lifespan* |

|---|---|---|

| High Friction | Constant rubbing against armature | 5-8 years |

| Water Exposure | Steam degrades spring tension | 3-5 years |

| Overloading | Extra strain increases wear rate | 2-4 years |

Based on LG/Samsung service data for standard home use.

④ Quick Diagnostic Guide

Before You Buy Replacements

- Locate the brushes: Usually behind a panel near the motor (consult manual)

- Measure them: New brushes = ~1.5 inches; Replace if < 0.25 inches

- Check for damage: Cracked brushes or corroded springs mean immediate replacement

Pro Tip

Take a photo of brush orientation before removal – incorrect installation can damage the armature!

⑤ Beyond Carbon Brushes: Other Common Drum Stoppers

While 60% of drum failures stem from brushes (Appliance Repair Journal, 2023), also consider:

- 🔗 Faulty Drive Belt: Learn how to check tension

- 🔗 Blocked Pump: Signs of drainage issues

- 🔗 Control Board Errors: Diagnose error codes